Product Description

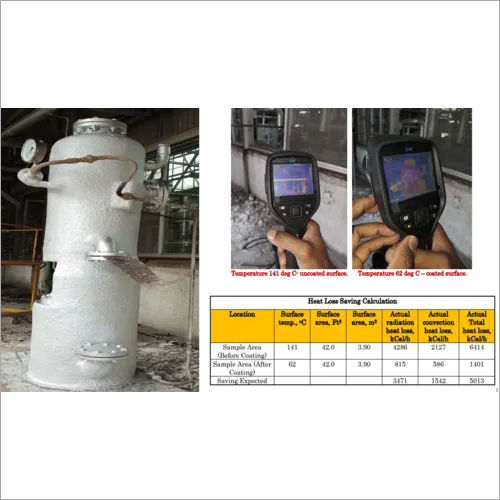

Heat Resistant and Thermal Insulation Coating Service is an important solution made to improve energy efficiency while protecting surfaces and improving their performance in many industrial applications and commercial uses. Such service involves special application coatings made to reduce heat transfer, ensure resistance to high temperatures, and prolong the life of structures and equipment. Application of underlays, which are used under our Heat Resistant and Thermal Insulation Coating Services, can be applied to walls, roofs, pipes, tanks, and even machinery, offering great thermal protection while decreasing losses through energy.

Advanced materials and coatings prevent damage from high temperatures and ensure the heat performance of a place does not deteriorate. Our service gives comfort, safety, and cost-savings from manufacturing facility to storage unit or house. They reduce carbon footprints as this leads to lesser energy consumption and thus will support green objectives. Such extensive Heat Resistant and Thermal Insulation Coating Services include consulting, surface preparation, application, and quality assurance that ensure that the outcomes last longer. Every project is tailored for application to deliver a smooth and effective implementation of the project.

FAQs:

Q: What are Heat Resistant and Thermal Insulation Coating Services?

A: These are coating services that specialize in applying the coating onto surfaces to resist high temperatures and promote thermal efficiency.

Q: Where can these coatings be applied?

A: They are ideal for roofs, walls, pipes, tanks, and industrial equipment.

Q: What benefits do these coatings provide?

A: They improve energy efficiency, reduce heat transfer, and protect surfaces from thermal damage.

Versatile Application AreasOur coating services are engineered for multiple surfaces including metal, concrete, roofs, pipelines, and storage tanks. This flexibility allows for seamless integration into industrial, commercial, and domestic environments, addressing diverse insulation and heat resistance needs, while providing a smooth, matt, or glossy finish as required.

Superior Heat and Weather ResistanceWithstanding temperatures up to 250C or as customized, our coatings are crafted for peak performance. Engineered to be eco-friendly and to deliver excellent adhesion and weather resistance, they reduce thermal transfer, help conserve energy, and extend the lifespan of your infrastructure.

Custom Solutions NationwideEach project undergoes a detailed site survey to ensure coverage area, coating thickness, and finish match your specifications. Serving all over India, we align our service process to your operational timelines, supporting both online and offline payments for added convenience.

FAQs of Heat Resistant and Thermal Insulation Coating Services:

Q: How is the heat resistant and thermal insulation coating applied to different surfaces?

A: After an onsite survey, our technicians prepare the surface, ensuring it is clean and ready. The coating is then professionally applied using tools suitable for the materialwhether it is metal, concrete, pipelines, or roofsensuring optimal adhesion and finish.

Q: What surfaces and industries can benefit from this service?

A: Our coating service is suitable for metal, concrete, roofs, storage tanks, and pipelines across industrial, commercial, and domestic settings, offering protection and insulation wherever heat resistance is essential.

Q: When should I consider applying a thermal insulation coating?

A: Thermal insulation coatings should be considered during new constructions, refurbishments, or when existing surfaces are exposed to high temperatures or fluctuating weather conditions that demand energy efficiency and protection.

Q: Where can this coating service be provided?

A: We deliver the service at your project site, anywhere in India. The process starts with a customized site survey to assess the required area, thickness, and finish.

Q: What is the process for determining coating thickness and color options?

A: Coating thickness and color are determined based on project requirements discussed during the site survey and consultation, ensuring the solution meets both technical and aesthetic expectations.

Q: How does this coating improve energy efficiency and safety?

A: By reducing thermal transfer and minimizing heat absorption or loss, the coating contributes to energy savings. Its high adhesion and weather resistance also improve structural safety and longevity.

Q: What makes this service environmentally friendly?

A: Our coatings contain low levels of volatile organic compounds (VOC) and are designed to be eco-friendly, contributing to a safer indoor and outdoor environment.