Product Description

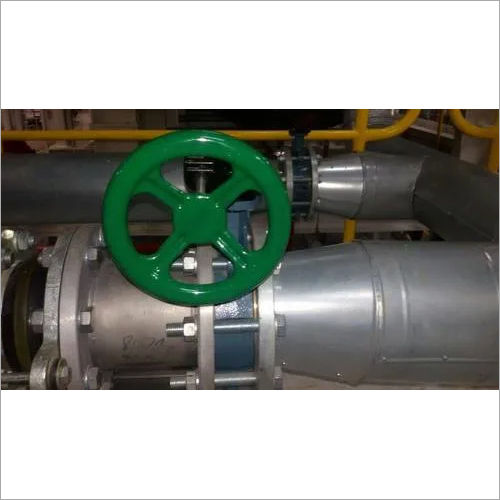

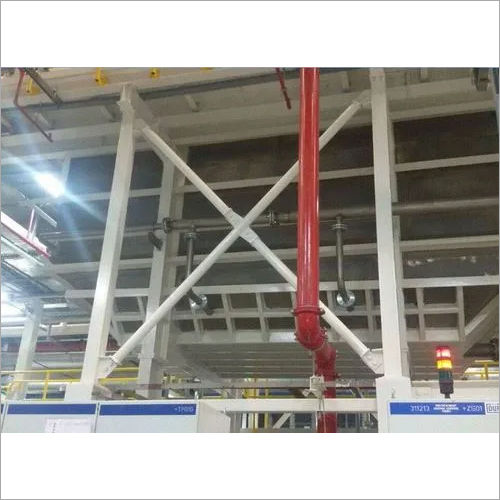

Exposed Steel Anti Corrosive Polyurethane Coating allows for usage of the steel in areas of high moisture or marine climate. It is most often used to avoid the development of corrosion on the metal and hence to try to preserve its reliability. Ironically, steel can corrode after many years and therefore its strength reduces and it can hardly support structures. This loss, therefore, can be efficiently checked by using the Exposed Steel Anti Corrosive Polyurethane Coating. The application is implemented by professionals who select the finest materials and properly adhere to a range of procedures that only provide the highest degree of corrosion protection. The coating therefore is intended to cover the exposed steel to shield it from the impact of water, salts, and other factors that may harm steel. Priced reasonably, the Exposed Steel Anti Corrosive Polyurethane Coating is available in specific formulations for different industries where the application is required with optimum corrosion resistance to increase the life cycle of the structure.

FAQs:

Q: What is the purpose of Exposed Steel Anti Corrosive Polyurethane Coating?

A: The Exposed Steel Anti Corrosive Polyurethane Coating helps in preventing corrosion on steel by moisture and rough climatic conditions.

Q: How long does Exposed Steel Anti Corrosive Polyurethane Coating last?

A: The coating provides long-lasting protection for several years and depends on the environment and its maintenance.

Q: Can Exposed Steel Anti Corrosive Polyurethane Coating be applied to any metal surface?

A: Yes, it is suitable for steel surfaces exposed to moisture or marine weather as it offers a good protective function against corrosion.

Advanced Protection for Exposed SteelThis polyurethane coating is meticulously engineered to shield exposed steel structures from the harsh effects of corrosive environments. Its combination of high adhesion strength and chemical resistance ensures long-lasting performance, making it ideal for industrial, commercial, and infrastructure applications. With a recommended dry film thickness of 50-100 microns, it consistently delivers comprehensive coverage and protection against rust and degradation.

User-Friendly Application and Versatile UseExposed Steel Anti Corrosive Polyurethane Coating suits both single and two-pack systems, featuring a straightforward 4:1 mix ratio for ease of preparation. Designed for application with brush, roller, or spray, it adapts to varied site conditions and project requirements. The fast-drying formula enables quick turnaround times, while its compatibility with epoxy primers enhances its versatility for multi-layer protection systems.

FAQs of Exposed Steel Anti Corrosive Polyurethane Coating:

Q: How should the Exposed Steel Anti Corrosive Polyurethane Coating be applied for optimal results?

A: For best protection and finish, apply the coating using a brush, roller, or spray at the recommended dry film thickness of 50-100 microns. The surface must be prepared, cleaned, and primed, ideally with a compatible epoxy primer, before use. Mix thoroughly (if two-pack, base:hardener at 4:1 by volume), and use polyurethane compatible thinner for proper consistency.

Q: What are the main benefits of using this polyurethane coating on steel surfaces?

A: This coating delivers high corrosion resistance, excellent UV and chemical stability, and superior salt spray endurance. These features help extend the lifespan of steel structures, maintain aesthetic appeal with a glossy finish, and reduce maintenance frequency and costs over time.

Q: When will the coating be fully cured after application?

A: Full cure is achieved in 7 days at standard conditions (25C). Initial surface drying takes approximately 30 minutes, and the coating reaches a hard dry state within about 8 hours post-application.

Q: Where should I store unused polyurethane coating material?

A: Store the coating in a cool, dry place away from direct sunlight, ideally in its original, tightly sealed tin or drum packaging. This ensures a shelf life of up to 12 months and preserves its quality for future use.

Q: What safety precautions should be observed during the application process?

A: During application, work in well-ventilated areas, and always wear suitable protective equipment such as gloves, safety goggles, and respirators to avoid inhalation or skin contact. Clean tools immediately with polyurethane compatible thinner to avoid residue buildup.

Q: Is this coating suitable for use with other primer systems?

A: Yes. The product is compatible with epoxy primers, which can be applied to steel substrates for enhanced multi-layered protection against corrosion.